Categories

- Application (4)

- Jewelry (1)

- Electric Motor (1)

- Power & Transformer (1)

- Copper & Aluminum Joint (1)

- Videos (12)

- News (6)

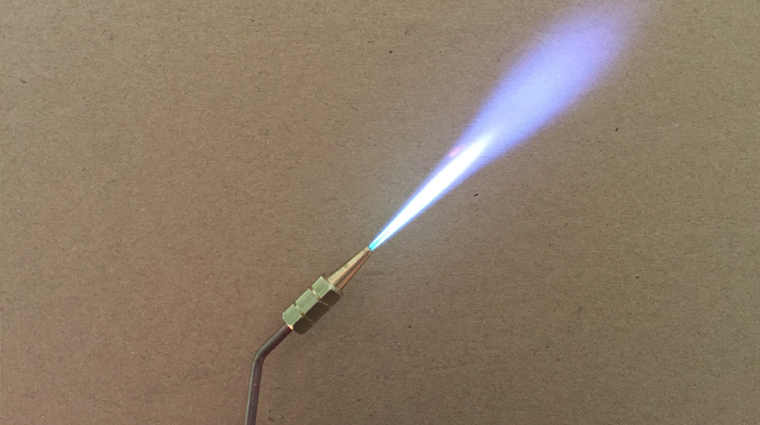

Gas welding is also called brazing, it uses solder material(also called welding rod) with lower melting point than welding parts. It will produce high temperature flame to heating welding parts and melting welding rod when combustible gas and combustion-supporting gas are mixed and burned in an oxyhydrogen welding torch. In practical application, this welding process is often used in copper tube welding.

1.Gas pressure adjustment

At first, connect power cord, and turn on the power switch. When the machine system loading, please press button for gas production. Secondly, turn off the flame torch’s valve. When the pressure gauge rises to 0.05Mpa, turn on the flame torch’s valve.

2.Ignition method

Before ignition, the flame torch nozzle should be tested if it produce much gas.It’s forbidden to ignition when producing less gas. Using the igniter to ignite,you should pay attention to protect yourself not to get burnt when ignition because the temperature of oxyhydrogen flame is very high.

3.Oxy-hydrogen gas welding operational method

Copper pipe welding need the length of the flame to be 20-30cm.It will produce the carbonizing flame which is not suitable for welding operation when the fuel gas output larger than oxygen output.Using the torch heat the copper pipe joint until the welding joint is dark red.The welding rod can be take down when put in the welding rob and wrap the melted electrode around the solder joint more than 0.8cm.

4.Oxyhydrogen flame adjustment

The size of oxyhydrogen flame can be adjusted by gas valve. If you need the a low flame temperature, spree the flame to heat big area when welding or other heating process, you can add into the cooling liquid(Cooling liquid is a kind of carbonated liquid that is easy to vaporize. Common cooling liquid is alcohol, methyl alcohol, acetone, petroleum ether).

It is required that the final welded copper tube welding joint is smooth and flat without any holes or slag.Doing anti-oxidation treatment after copper pipe welding.

5.Why does copper pipe welding need to do anti-oxidation

If necessary anti-oxidation and anti-corrosion treatment is not carried out, the welding joint can be oxidized and corroded, the blackening of the welding joint means oxidation. This will affects the overall appearance of the equipment. Paint with red copper anticorrosive paint(not oil paint), copper paint have a good lead function and provides good oxidation protection for copper metal surface, which can prevent oxidation and corrosion.

Comparison of application effect of copper pipe welding after oxidation and blackening

Copper anticorrosive spray paint is sprayed directly on the surface of the tube. No baking after spray, repair the oxidation.

Method of application

1)Wipe the product with a towel to remove stains, grease, or oxide.

2)Shake the tank before use

3)Paint the product with copper anticorrosive paint, spray distance is recommended around 25cm

4)Paint finished

Okay Energy produce oxyhydrogen gas welding machine(water welding machine), take water as a working medium. The original is that water can be electrolyzed to form hydrogen and oxygen gas under certain conditions, the hydrogen gas as fuel, oxygen gas combustion, ignition to form oxy hydrogen flame.

Using the characteristics of high temperature, high energy and concentrated fire power of oxy- hydrogen flame, the welding parts of copper tubes need to be welded can be welded into balls instantly. The welding spot is firm and beautiful, no virtual welding, no black smoke, no exhaust gas.